Thursday, December 10, 2009

The recycle bags are finally done. I made two of the blue warp dominate bags, and two of the red weft dominate. Personally, I like the red bags better, but the blue have been getting more buzz from my friends. I donated one of each color to a charity auction at a local club I belong to yesterday. Both were bought by friends who are also fiber people (one quilter, one knitter).

Tuesday, November 17, 2009

The Recycle Adventure Continues

So - I finally got around to wet finishing the fabric. I keep procrastinating on digging out my old Singer Featherweight sewing machine and stitching up the finished project. In the meantime I took a break from bags and worked on some scarves. The one pictured here is a warp of viscose yarn and a weft of mercerized cotton in a 3/1 twill.

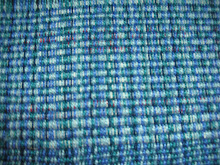

Since my friends are keeping me well supplied with Target bags, I decided to try something different. The blue fabric is warp faced - the Target bags are used as weft, but don't really show. This time I dressed the loom so that the fabric is weft faced (think rag rugs). I really like the way they are turning out!

Since my friends are keeping me well supplied with Target bags, I decided to try something different. The blue fabric is warp faced - the Target bags are used as weft, but don't really show. This time I dressed the loom so that the fabric is weft faced (think rag rugs). I really like the way they are turning out!

Sunday, October 18, 2009

The Fabric is woven, but the work is not over

I cut the fabric for the recycle bag project off the loom on Thursday, but there is still more to do before they are done.

The fabric itself is not done yet - it needs to be wet finished. The simple explanation is that the fabric is not ready until it has been washed and dried for the first time. Depending on the fabric in question, lots of things can happen during this process. Many fabrics become softer and more pliable. Many shrink. Wool fulls - the individual threads become thicker. Taken to the extreme - wool becomes felt. Often you treat the fabric more roughly than it should ever be treated again - hotter water temperature, hotter dryer, hard pressing with an iron. In the case of the bags, I plan to wash in warm water, air dry and skip ironing. Cotton can stand more heat, but obviously plastic bags are more delicate.

I also need to come up with handles or straps. I have had an Inkle loom for quite awhile, but have never used it. Inkle looms are used to make belts, straps, anything that is very narrow. So - I am learning how to use it while I make the handles. So far I am making lots of mistakes, but things should get better as I go along!

Last will being digging out my old workhorse Singer Featherweight sewing machine. It's older than I am, but it will handle just about anything.

The fabric itself is not done yet - it needs to be wet finished. The simple explanation is that the fabric is not ready until it has been washed and dried for the first time. Depending on the fabric in question, lots of things can happen during this process. Many fabrics become softer and more pliable. Many shrink. Wool fulls - the individual threads become thicker. Taken to the extreme - wool becomes felt. Often you treat the fabric more roughly than it should ever be treated again - hotter water temperature, hotter dryer, hard pressing with an iron. In the case of the bags, I plan to wash in warm water, air dry and skip ironing. Cotton can stand more heat, but obviously plastic bags are more delicate.

I also need to come up with handles or straps. I have had an Inkle loom for quite awhile, but have never used it. Inkle looms are used to make belts, straps, anything that is very narrow. So - I am learning how to use it while I make the handles. So far I am making lots of mistakes, but things should get better as I go along!

Last will being digging out my old workhorse Singer Featherweight sewing machine. It's older than I am, but it will handle just about anything.

Monday, October 12, 2009

Finally - pictures and fabric

Taking a day off from weaving to take care of other business - including getting pictures into the blog! If you look at the pictures from the bottom up (seems to be how blogs work), you can see the steps to "dress" the loom and create the fabric.

Learning to weave is never ending. First, there are all the terms. Most of them are very old, and not intuitive. I found at the beginning it was easiest just to go through the steps, and realize that my poor brain would finally absorb them. Of course, this is just one kind of loom (there are lots) and a very simple weave structure. I am learning so many new things with each project. With any luck this is keeping me young.

Learning to weave is never ending. First, there are all the terms. Most of them are very old, and not intuitive. I found at the beginning it was easiest just to go through the steps, and realize that my poor brain would finally absorb them. Of course, this is just one kind of loom (there are lots) and a very simple weave structure. I am learning so many new things with each project. With any luck this is keeping me young.

Wednesday, October 7, 2009

Thoughts on Green

I've got some pictures to post of the progress of my recycled bags - just taking awhile to do it. The joys of procrastination. I have been thinking way to much about what it means to be green.

So - the idea behind my project is to recycle plastic bags. I have asked my local buddies to save their Target bags for me. I am getting lots and lots of them. But I am also thinking about what it really means to recycle. The best use for these bags would seem to be to reuse them until they are falling apart, and then find another use for them. Most of us just don't do that. Using them to weave with at least means that they will get used over and over again.

Part of my recycle effort is too use left over cotton yarn from other projects - but I need to be honest with myself. It's not like I am going to throw this stuff out. It will get used for something, whether the bags, scarves, book marks, towels, mug mats - something. Not that I don't think this project is a good idea, or that I am not going to do it.

Then there is a bigger question of green fabrics. The mind goes immediately to the natural and organically grown plant fibers. Cotton is great to work with, but even grown organically it takes it toll on the planet. I must admit I really loved the mercerized cottons - strong, colorful. But of course it is chemically treated. I love rayon - especially rayon chenille. Gorgeous stuff. It is from plant fiber, but chemically processed. There has been a lot of buzz about bamboo - but that is also a rayon - so not as green as everyone assumed. Wool is pretty green, but I am quite allergic. I have some to make scarves with, but have hesitated to get started - I know I will pay a price.

Nothing is ever as simple as it seems.

So - the idea behind my project is to recycle plastic bags. I have asked my local buddies to save their Target bags for me. I am getting lots and lots of them. But I am also thinking about what it really means to recycle. The best use for these bags would seem to be to reuse them until they are falling apart, and then find another use for them. Most of us just don't do that. Using them to weave with at least means that they will get used over and over again.

Part of my recycle effort is too use left over cotton yarn from other projects - but I need to be honest with myself. It's not like I am going to throw this stuff out. It will get used for something, whether the bags, scarves, book marks, towels, mug mats - something. Not that I don't think this project is a good idea, or that I am not going to do it.

Then there is a bigger question of green fabrics. The mind goes immediately to the natural and organically grown plant fibers. Cotton is great to work with, but even grown organically it takes it toll on the planet. I must admit I really loved the mercerized cottons - strong, colorful. But of course it is chemically treated. I love rayon - especially rayon chenille. Gorgeous stuff. It is from plant fiber, but chemically processed. There has been a lot of buzz about bamboo - but that is also a rayon - so not as green as everyone assumed. Wool is pretty green, but I am quite allergic. I have some to make scarves with, but have hesitated to get started - I know I will pay a price.

Nothing is ever as simple as it seems.

Sunday, October 4, 2009

First hurdle, and the inventiveness of weavers (and husbands)

So - I started winding my warp this morning. Since I am mixing a bunch of left over yarn, I am winding four strands at a time unto my warping wheel. I have the cones on a cone stand, so the yarn is being pulled from the top. Let the tangling frustrations begin! I need a cone rack so I can pull from the sides. Very creative husband has already made me a narrow table for the tools I need to wind pirns, and make skeins into balls. So - off to the local Ace Hardware to get dowels and hardware to add a spool rack feature. When we got home he made the modifications in a few minutes. Handy husbands are very handy!

One of the fun aspects of weaving is the inventiveness of weavers. There are lots of tools you can buy, but also lots of things you can put together on your own. Hardware and office supply stores offer never ending possibilities.

One of the fun aspects of weaving is the inventiveness of weavers. There are lots of tools you can buy, but also lots of things you can put together on your own. Hardware and office supply stores offer never ending possibilities.

Starting on a green project

I have read a couple articles about using recycling plastic bags by using them in weaving. I thought it would be fun to try, and of course the first thing that came to mind was to make shopping bags. So, I started designing in my head. The first thought was that I think plastic bags are ugly, so I didn't want them to show as part of the design. This means that I needed to do a warp-faced weave. (Not a weaver? Warp is the yarn that runs from the back to the front of the loom. Warp-faced means that only the warp will show on the finished the fabric. The weft is the yarn that runs from side to side - in this case strips from the plastic bags.) I have lots of 3/2 cotton in various shades of blue from other projects - this should make a good strong strong warp.

So - I also needed to figure out what size I needed. One of the things I have objected to with plastic bags is that they are too small and that stuff just flops around in them. So I knew I wanted something like a paper grocery bag, but I thought that would be too tall. Then I went to Coldwater Creek, and realized I really like the shape of their bags. Since I scored some good sale buys, I came home with a template!

A last consideration was handles. I want really, really strong handles. I have an Inkle loom (for making belts, straps, etc) that I have never used. So - I plan to weave straps on the Inkle loom that will go all the way around the bottom of the bag.

So - I also needed to figure out what size I needed. One of the things I have objected to with plastic bags is that they are too small and that stuff just flops around in them. So I knew I wanted something like a paper grocery bag, but I thought that would be too tall. Then I went to Coldwater Creek, and realized I really like the shape of their bags. Since I scored some good sale buys, I came home with a template!

A last consideration was handles. I want really, really strong handles. I have an Inkle loom (for making belts, straps, etc) that I have never used. So - I plan to weave straps on the Inkle loom that will go all the way around the bottom of the bag.

Subscribe to:

Posts (Atom)